Biogenic carbon dioxide circulates naturally around the ecocycle that is firmly integrated into our business. The trees that grow in our forests absorb carbon dioxide, and after harvesting, the carbon dioxide continues to be stored in our wood products. When the products are finally burned as bioenergy (replacing fossil energy), the carbon dioxide is released, to be absorbed once again by new growing trees.

Circularity – integral to our business

Growing, healthy forests, efficient management of raw materials and circular ecosystems are vital to our profitability. They are also the cornerstone of a genuinely sustainable business.

What is circularity?

Circularity means that resources are used, reused and recycled to prevent waste at the end of the chain. A circular economy that conserves value paves the way for a sustainable future and a healthy planet for future generations. It is all about a holistic approach and an industrial system in which value is retained and recreated, with as little as possible thrown away.

A shift to renewable energy

The circular economy means shifting to renewable energy, phasing out harmful substances and eliminating waste through the conscious design of materials, products, systems and business models.

Our circular business

Our business model is circular. The forest ecocycle gives us our wood, which is refined and made into products, which our customers can then refine in their turn. As the lifecycle draws to a close, the products can be recycled and come back to life in a new form, or be useful as biofuel.

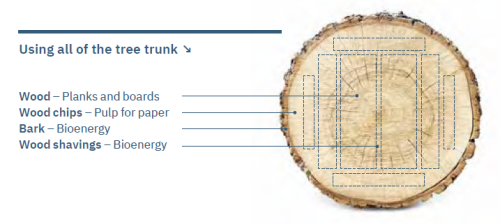

We like to say that we grow houses. By which we mean that we manage our forests in a way that yields the maximum quantity of rectangular planks from the growing trees. And we turn whatever is left over – wood shavings, bark and branches – into paper, paperboard and bioenergy. Nothing goes to waste!

Organic material from the water treatment process is extracted and sold on as natural fertiliser, and steam from our mills at Iggesund and Braviken is used in the drying processes at the integrated sawmills.

Sustainability

The circular ecocycle

Together we are circular

Our customers, partners, employees and, not least, the users of our products are all part of Holmen’s circular business. Every new relationship is an opportunity to expand the positive ripple effect of our actions. Together, we are growing a sustainable future.

Please accept Marketing, Preferences and Statistics cookies to view this content.

Recycled paper grows in the forest

We take whatever is left over of the wood raw material after the production of sawn wood products – wood chips, bark and branches – and turn it into paper and paperboard. Paper produced from fresh fibre tops up the recycled paper system when it is recycled. This is essential, as there is a limit to the number of times fibre can be recycled into paper, so fresh raw material is needed to keep the cycle going.

By-products become new resources

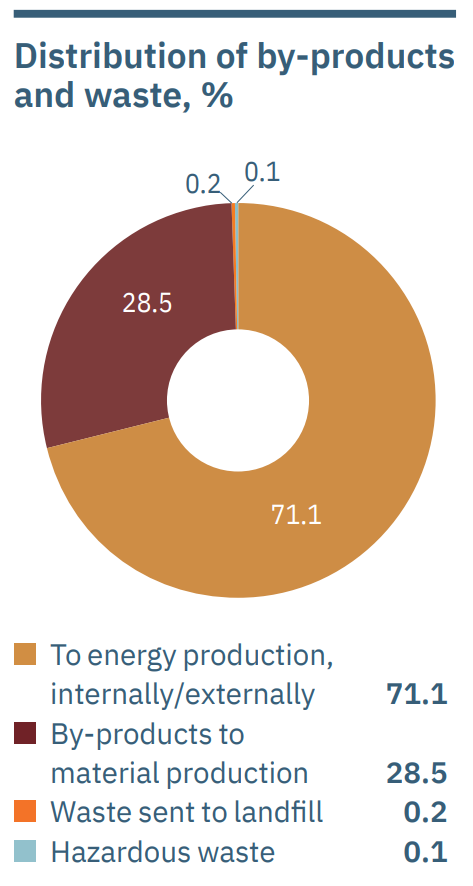

Over the years, we have made huge efficiency gains in our use of energy, water and chemicals. At the same time, we have increased the reuse of any waste that is generated. For example, wood waste products from the sawmills are used to produce paper and paperboard, as well as electrical and thermal energy at the mills. Organic material from the water treatment process is sold on as natural fertiliser, and steam from our mills at Iggesund and Braviken is used in the drying processes at the integrated sawmills.

Since 2005, we have managed to cut our use of fossil fuels at our mills by almost 90 per cent.

You can find out more about by-products and waste from our operations here.

7,2 million tonnes of climate benefit

We are part of a value chain that creates climate benefit in several areas, amounting to 7 million tonnes of carbon dioxide in year 2021. And it is clear that our greatest climate benefit comes from forest products replacing fossil alternatives.

+1.9

CO2 uptake in the annual increase in the volume of standing timber in Holmen’s forests, plus CO2 stored in Holmen’s products.

+6

Substitution, where the renewable products and the renewable energy Holmen sells replace fossil alternatives.

- 0,7

Holmen’s fossil emissions. Over 80% of these are generated from transport and procurement.