Climate change is one of the most critical issues for our future, and many companies have chosen to link their sustainability work to the UN Sustainable Development Goals and the ambition of the Paris Agreement to limit global warming to 1.5°C.

More and more purchasers of book, magazine and advertising paper therefore want to know what climate footprint different printed material has, in order to compare and make the best choices from a climate perspective. A few years ago, an international calculation tool was developed to help companies in the graphic industry to work out this very figure.

“There are now around 90 printing firms in Europe that use the ClimateCalc tool. In Sweden, there are nine, with a handful also currently in the process of obtaining their certification."

"We are seeing that the more purchasers request data on greenhouse gas emissions, the more interest there is in the tool across the industry,” says consultant Magnus Brolin from Altamont Media, who works on behalf of the Swedish Graphic Industries Federation to help Swedish companies with their certification.

Intergraf standards enable comparisons

ClimateCalc was developed by the European trade association Intergraf and is based on both ISO standards and the Greenhouse Gas Protocol.

“Intergraf has honed a standard that works for the printing industry, enabling comparisons as the number of users grows. As well as allowing the climate footprints for different printed material to be compared, the tool also makes it possible for the printing firms to compare themselves with each other, which could boost sustainability work.”

How ClimateCalc works

To calculate the climate footprint of printed material, you need to know the greenhouse gas emissions that occur during its life cycle – from harvesting and pulp production to the point when the paper is sent for recycling. The Greenhouse Gas Protocol, the most established standard for reporting greenhouse gas emissions, divides emissions up into three scopes. Scope 1 covers the direct greenhouse gas emissions over which the business has control, such as emissions from company cars. Scope 2 covers indirect emissions associated with the consumption of purchased electricity and district heating. In Sweden, Scopes 1 and 2 can account for up to 10 per cent of emissions, although the figure is usually lower.

Scope 3 covers the indirect greenhouse gas emissions that occur beyond the boundaries of the business. These relate to things like the manufacture of paper and chemicals, employees’ travel to and from work, and deliveries to customers. Although the indirect emissions cannot be directly controlled by the printing firms, they can be influenced, for example, by choosing paper, chemicals and transport solutions with a low climate impact. The item responsible for the most greenhouse gas emissions on a printing job is the manufacture of the paper, which is highly energy-intensive. This means it matters where the paper was made.

Fossil free energy makes a large difference

“The energy we use in Sweden is almost entirely fossil free, being largely based on hydro, nuclear and wind power. Countries such as Poland and Germany, on the other hand, have a number of coal-fired power stations, which generate considerable greenhouse gas emissions.

This is reflected in the factor used to calculate emissions in ClimateCalc. In Sweden it stands at 0.054 kilos of greenhouse gases per kilowatt-hour, in Denmark it is 0.312 kilos, in Germany the figure is 0.637 kilos and in Poland it is 1.069 kilos.”

“Although a paper from Poland might be SEK 0.75 cheaper per kilo, it generates 20 times higher emissions. Having the figures in black and white makes it more difficult to end up with a poor climate choice. For example, we are seeing a number of Danish publishers opting to use Swedish paper because it is better from a climate perspective.”

Use the supplier's Paper Profiles and Carbon Footprint declarations

The companies signed up to ClimateCalc begin by working out the emissions from their business. It is then possible to produce a calculation for a specific printed product. Following the initial certification, there are then annual audits to check whether that certification can be retained.

“It can take a few weeks to gather data from your suppliers and enter it into the system, but then you just need to update the figures each year.”

Magnus Brolin is confident that most suppliers of, for example, electricity, chemicals, paper and transport services have data on their greenhouse gas emissions that they are happy to share.

Just like Holmen, many other major paper manufacturers also use the industry-wide environmental product declaration Paper Profile.

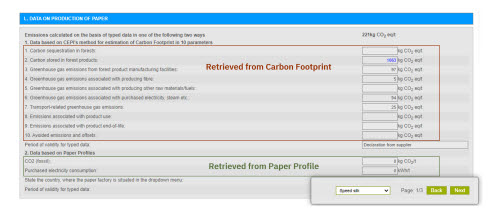

The supplier's declarations Carbon Footprint and Paper Profile give information such as emissions to water and air for different types of paper. Holmen is among the suppliers that keep their declarations available for download online. The printing firms can enter this data directly in ClimateCalc. Click the image below to show it in a larger format.

Carbon offset for climate neutral printing

Once the calculations in ClimateCalc have been completed, the printing firm’s customers can access figures on the climate footprint of each individual printed product. The customer can then decide whether they want to go down the route of carbon offsetting. This can be done by either the customer or the printing firm.

While ClimateCalc has allowed the graphic industry to take a huge step forward in climate terms, there has still been some criticism of the fact that not all emissions are included. Things like flights, cleaning and waste, for example, are not incorporated into the figures.

“The ambition moving forward is to cast the net wider and bring more categories of emissions into the calculation tool, but those with the greatest impact, such as paper and electricity, are already in there.”

Make fair comparisons

The question some might ask is whether paper should be used at all, or whether it is better to focus on digital mailshots and magazines.

“It is easy to forget what an incredible amount of energy it takes to keep all the servers running, and if this electricity is produced in countries that rely heavily on fossil energy, then that is terrible for the climate,” Magnus Brolin concludes.

Author: Jacqueline Fahlander